PROJECT

Bioinspired soft robotic systems for cognitive production

Summary

The objective of the BIOIC project is to setup a framework for a long-lasting strategic research collaboration between Fraunhofer and University of Naples Federico II in the field of bioinspired soft robotic technologies, with a focus on cognitive production systems and biological transformation. The project will develop multiple core technology platforms to be used in different scenarios and different application areas. Two research directions have been established, one on soft articulated robots and one on soft-bodied robots, the latter at two scales: macro and micro. Two main scenarios are foreseen, the first focused on robotic autonomous operations, the second focused on robotic collaborative tasks. A third scenario is indeed related to soft micro-robots acting as building blocks for future bottom-up biomanufacturing processes. For each scenario, multiple use-cases have been defined to be carried out within the project. Industrial companies from Germany and Italy have also been involved in the BIOIC project as part of an advisor group that accompanies the project from an industrial perspective.

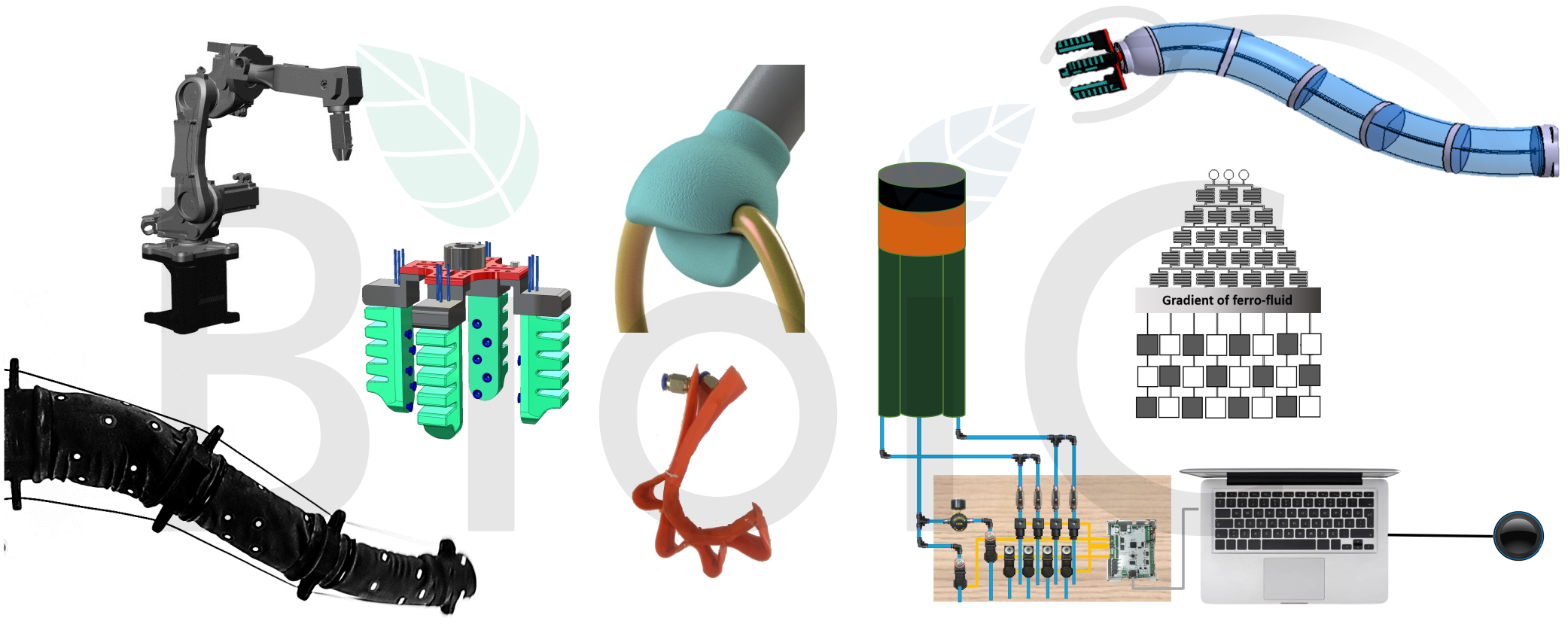

Robots

- T1: Bimanual soft articulated robot

- T2: Soft robotic grippers

- T3: Soft continuum robots

- T4: Soft growing robots

- T5: Soft micro robots

Robots applied in different scenarios

Scenario #1: Autonomous Cognitive Production

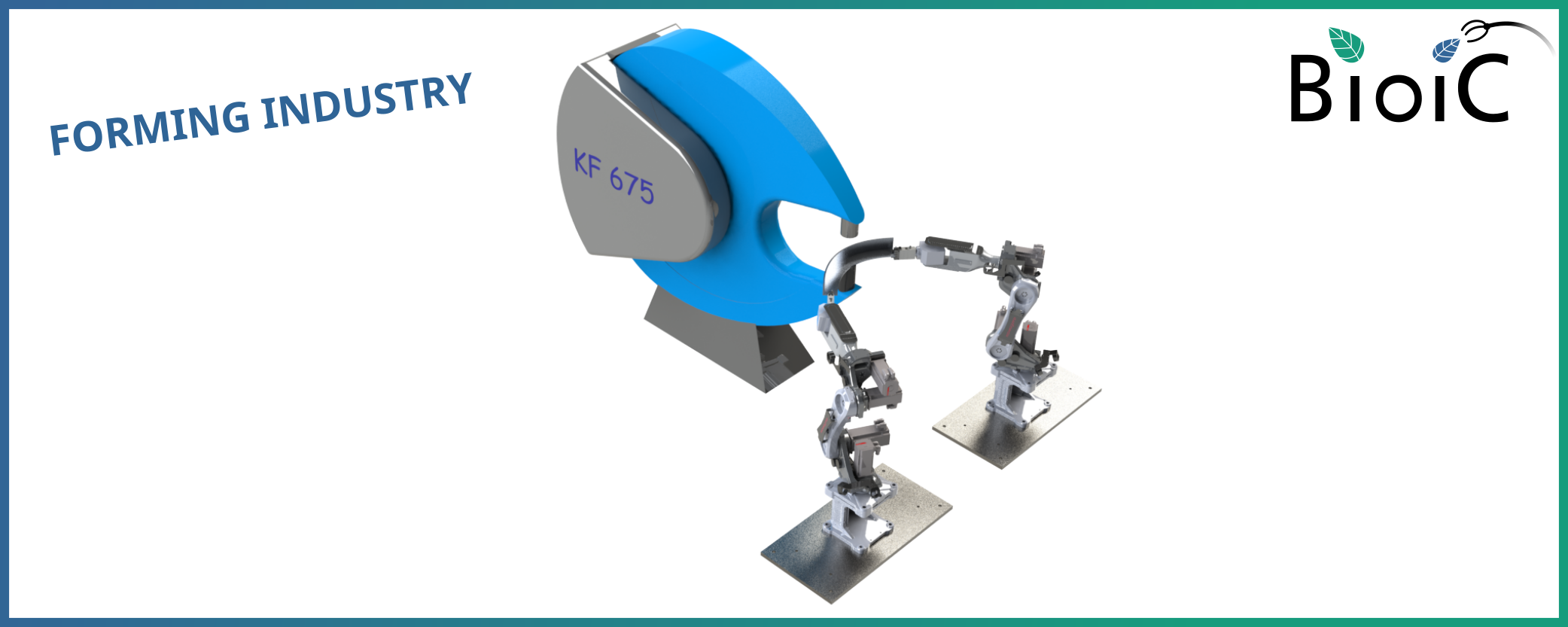

Use case #1.1: Forming of metal sheets using bimanual soft articulated robot taking inspiration from human movements

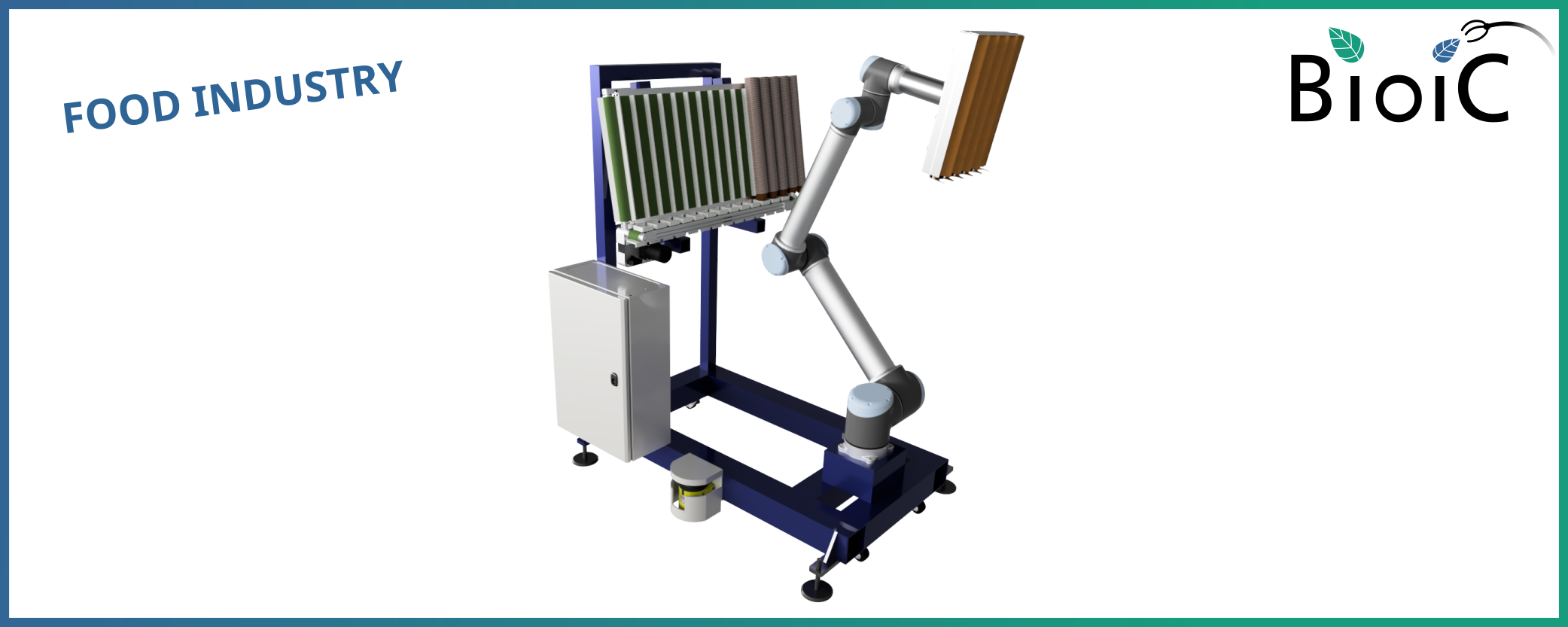

Use case #1.2: Manipulation of stacked objects using soft robotic grippers

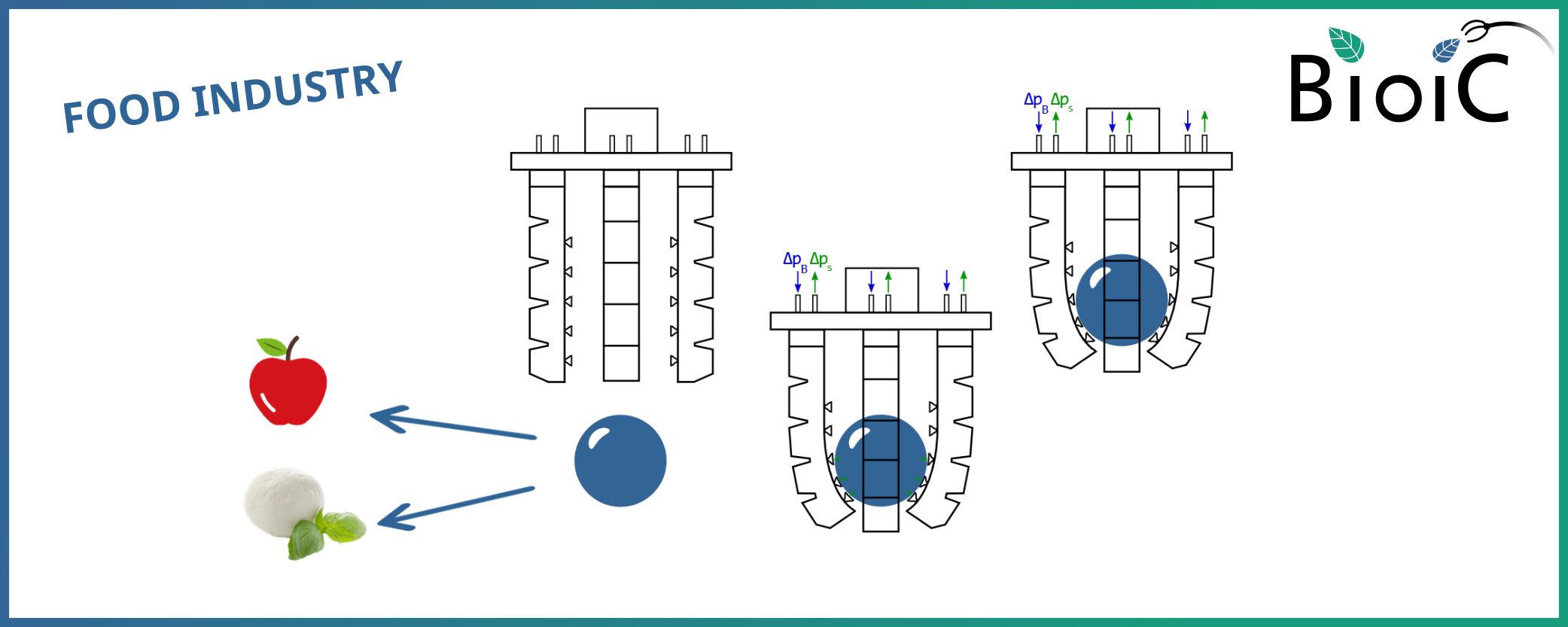

Use case #1.3: Manipulation of spherical-like smooth agrifood products

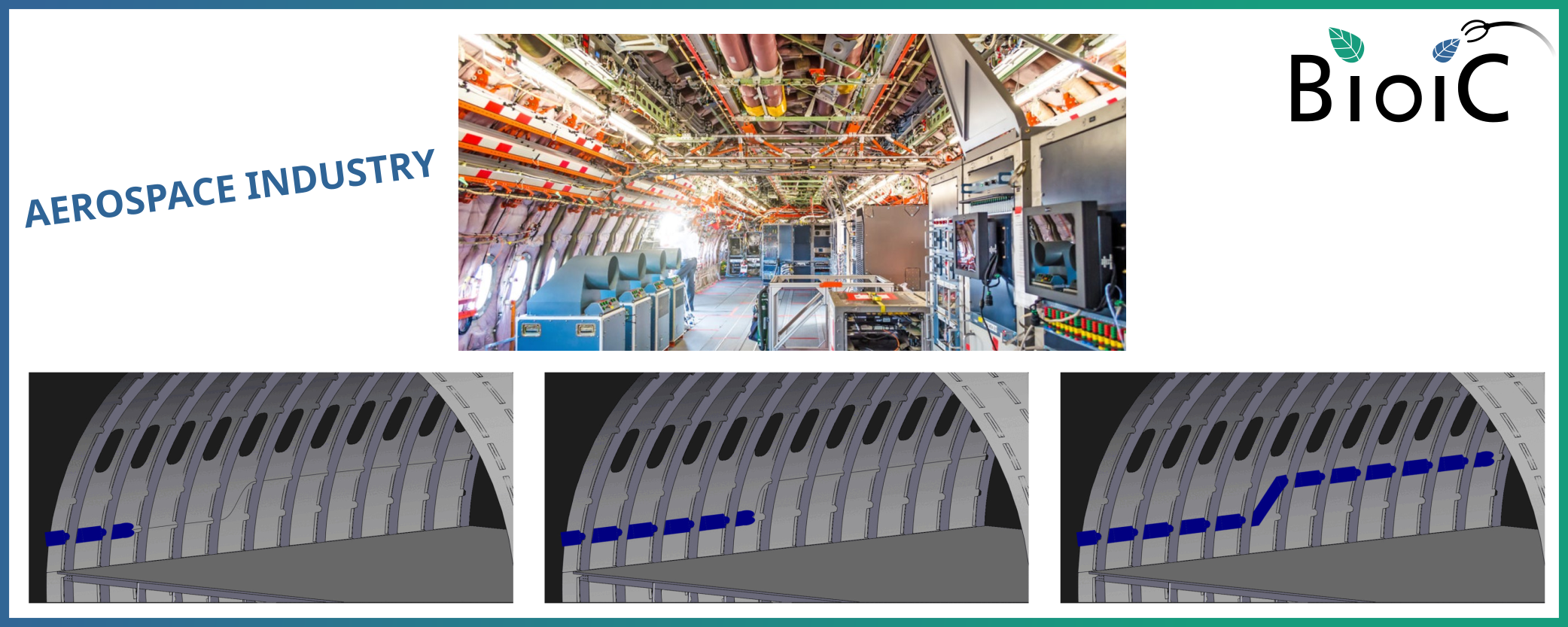

Use case #1.4: Automatic installation of cables in aircraft fuselage using soft robots

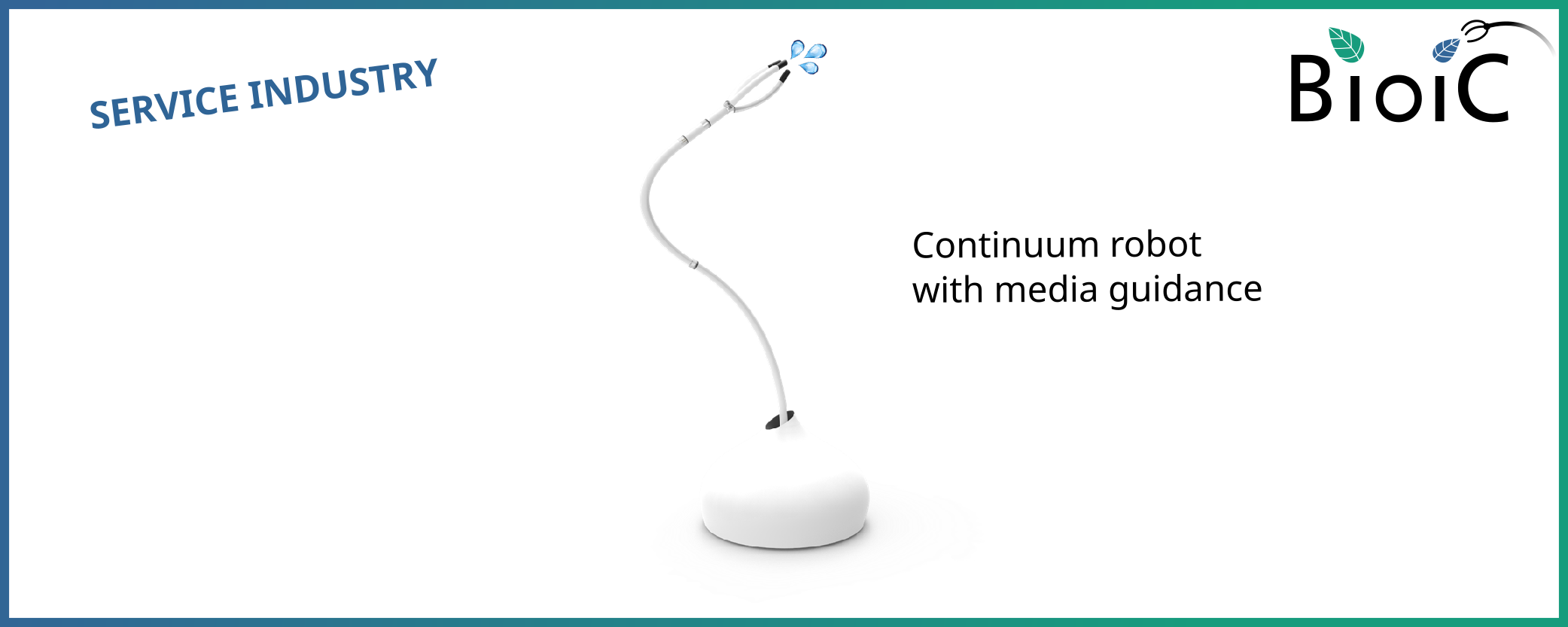

Use case #1.5: Media transportation using soft robots for fluid handling applications

Scenario #2: Human - Robot Collaboration

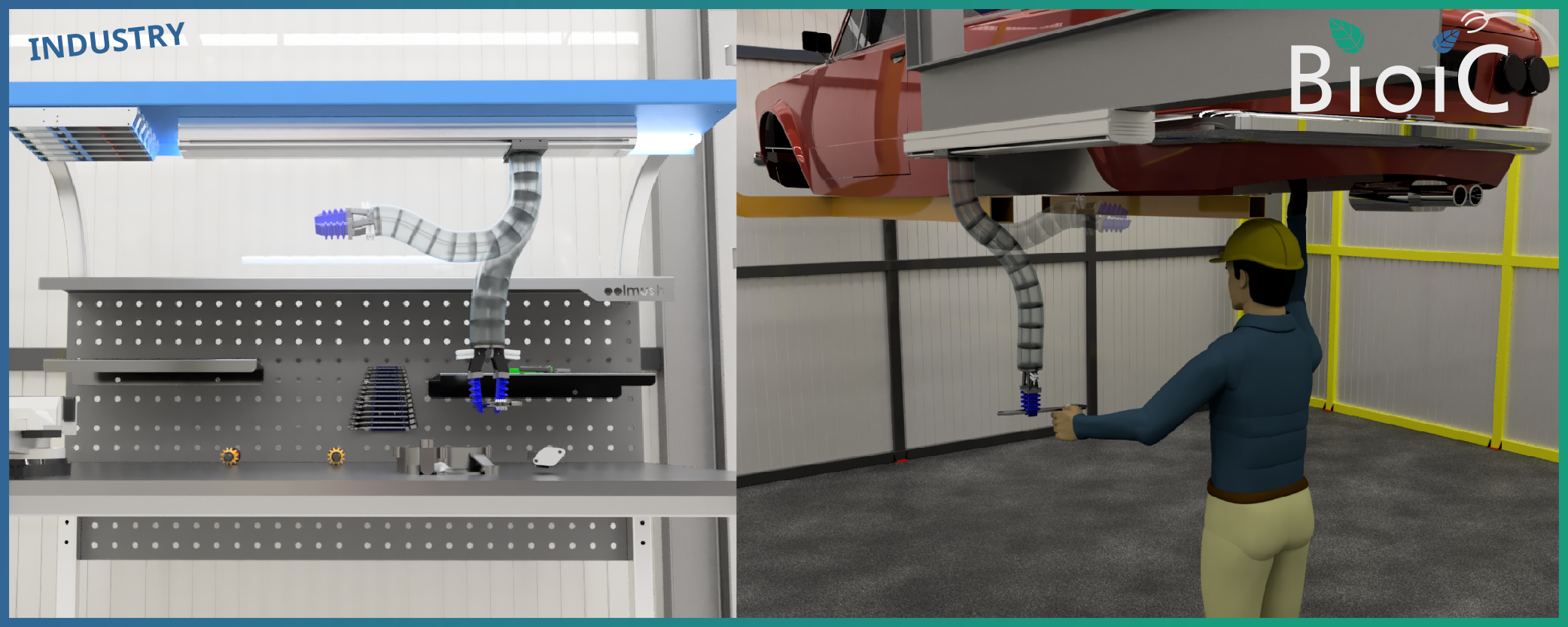

Use case #2.1: Human assistant for industrial tasks

Use case #2.1: Human assistant for service tasks

Scenario #3: Bottom-up Biomanufacturing

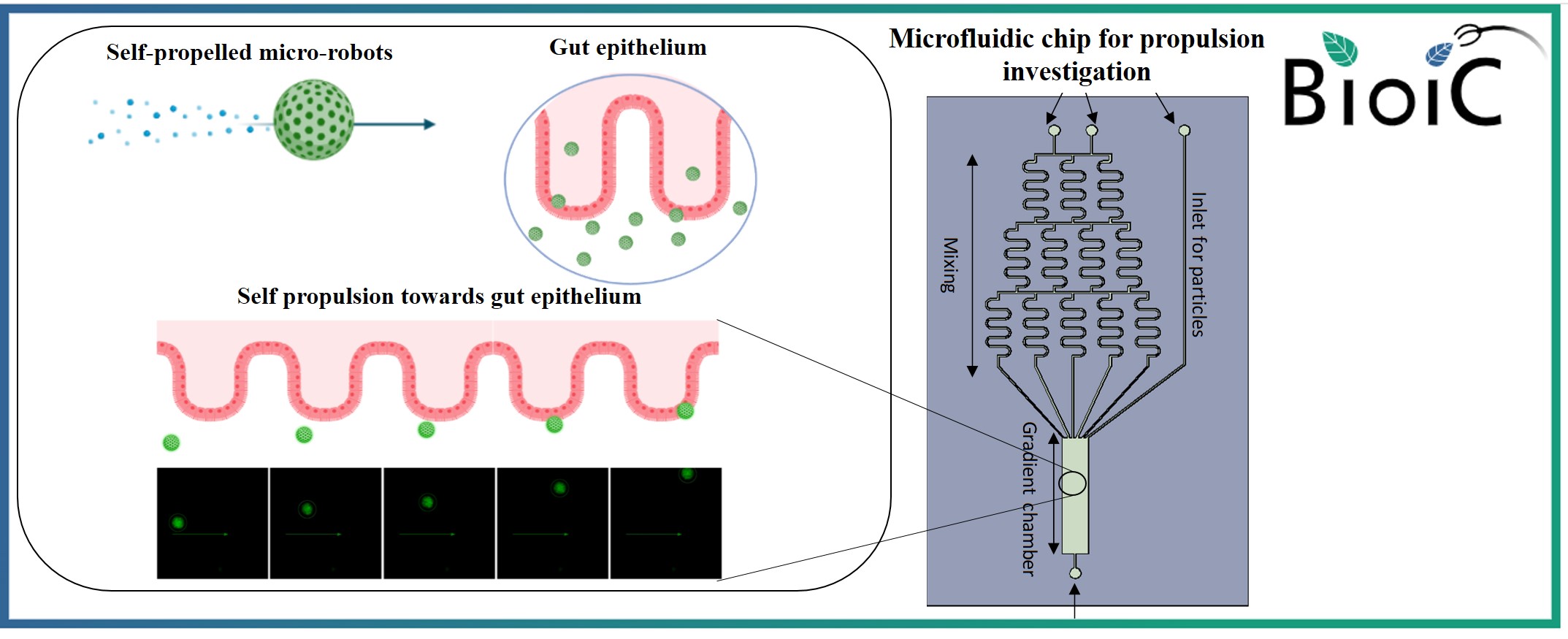

Use case #3.1: Microparticle-based microrobots

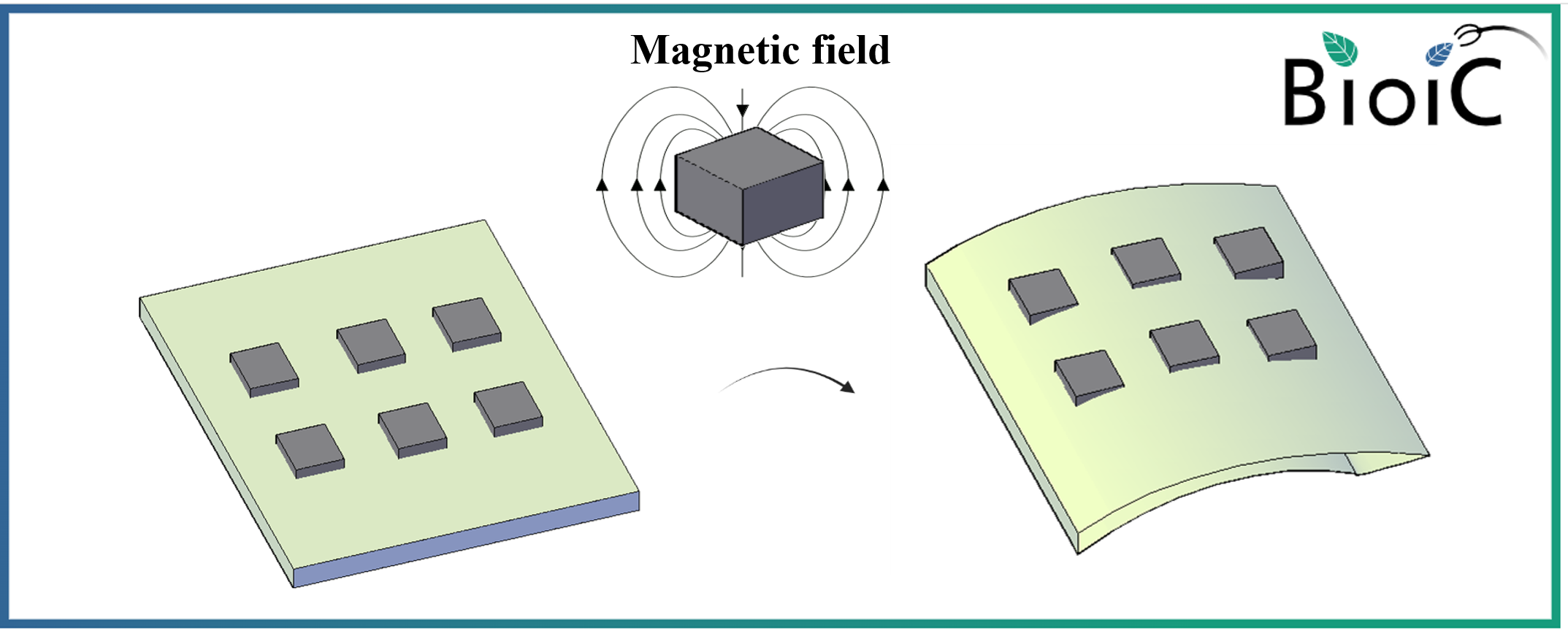

Use case #3.2: Magnetically actuable microrobots